Check valves are crucial components in systems where preventing backflow is essential to protect equipment and maintain efficient operation. These valves are commonly used in applications such as water and wastewater systems, chemical processing, and oil and gas industries. The primary function of a check valve is to allow fluid to flow in one direction while automatically preventing reverse flow. This is achieved through a variety of designs, including swing, lift, and ball check valves. By preventing backflow, check valves protect pumps, compressors, and other critical equipment from potential damage, ensuring the longevity and efficiency of the entire system.

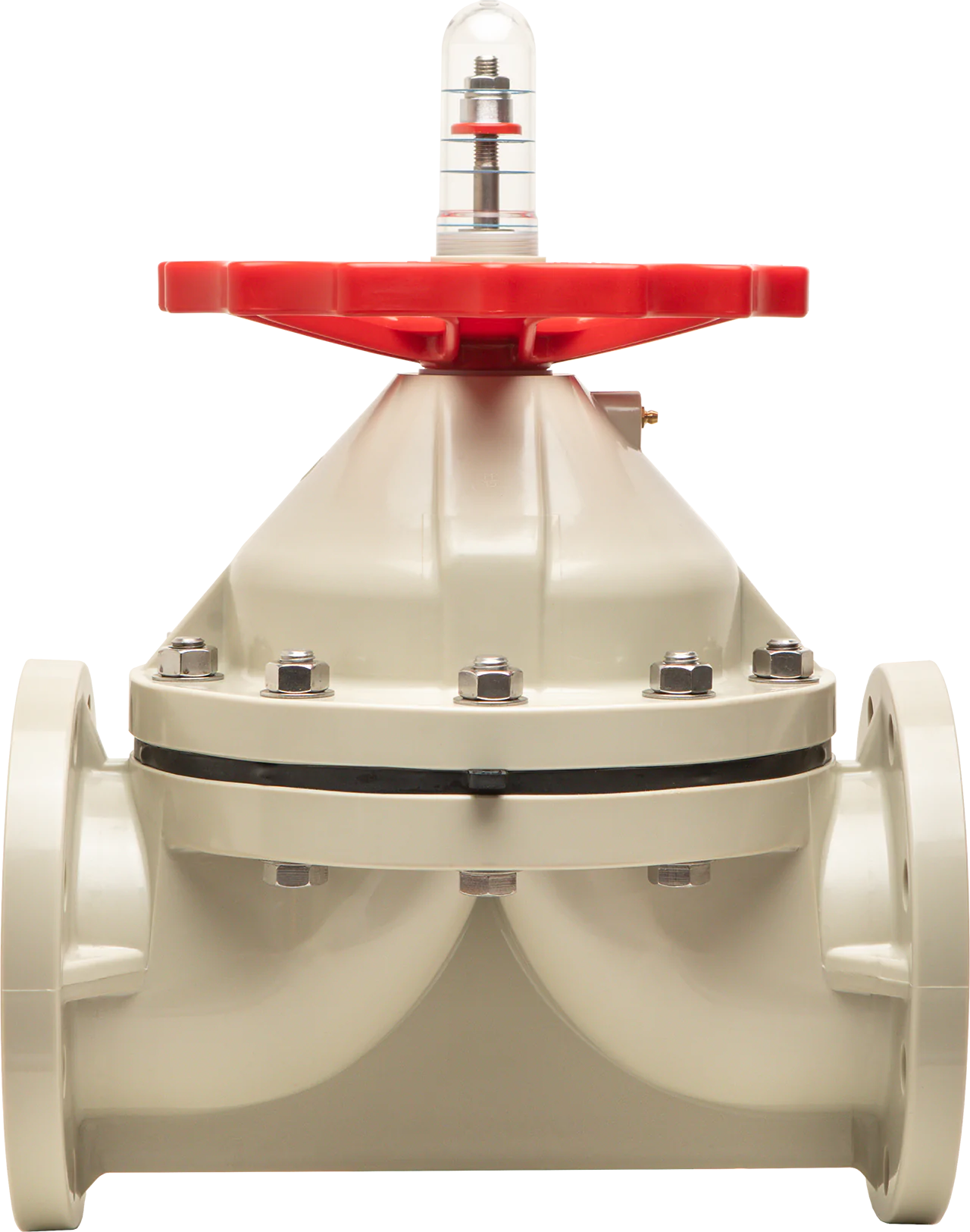

Diaphragm valves are designed to provide exceptional leak-proof performance, making them ideal for applications in hygienic and corrosive environments. These valves are widely used in industries such as pharmaceuticals, food and beverage, and chemical processing, where maintaining a sterile and contamination-free process is crucial. The diaphragm valve operates by using a flexible diaphragm that presses against a seat to control the flow of fluids. This design ensures a tight seal, preventing any leakage and minimizing the risk of contamination. Diaphragm valves are also easy to clean and maintain, which is essential in applications requiring frequent sterilization. Their simple and robust design allows for reliable operation and precise flow control, making them a versatile and dependable choice for a wide range of industrial processes.