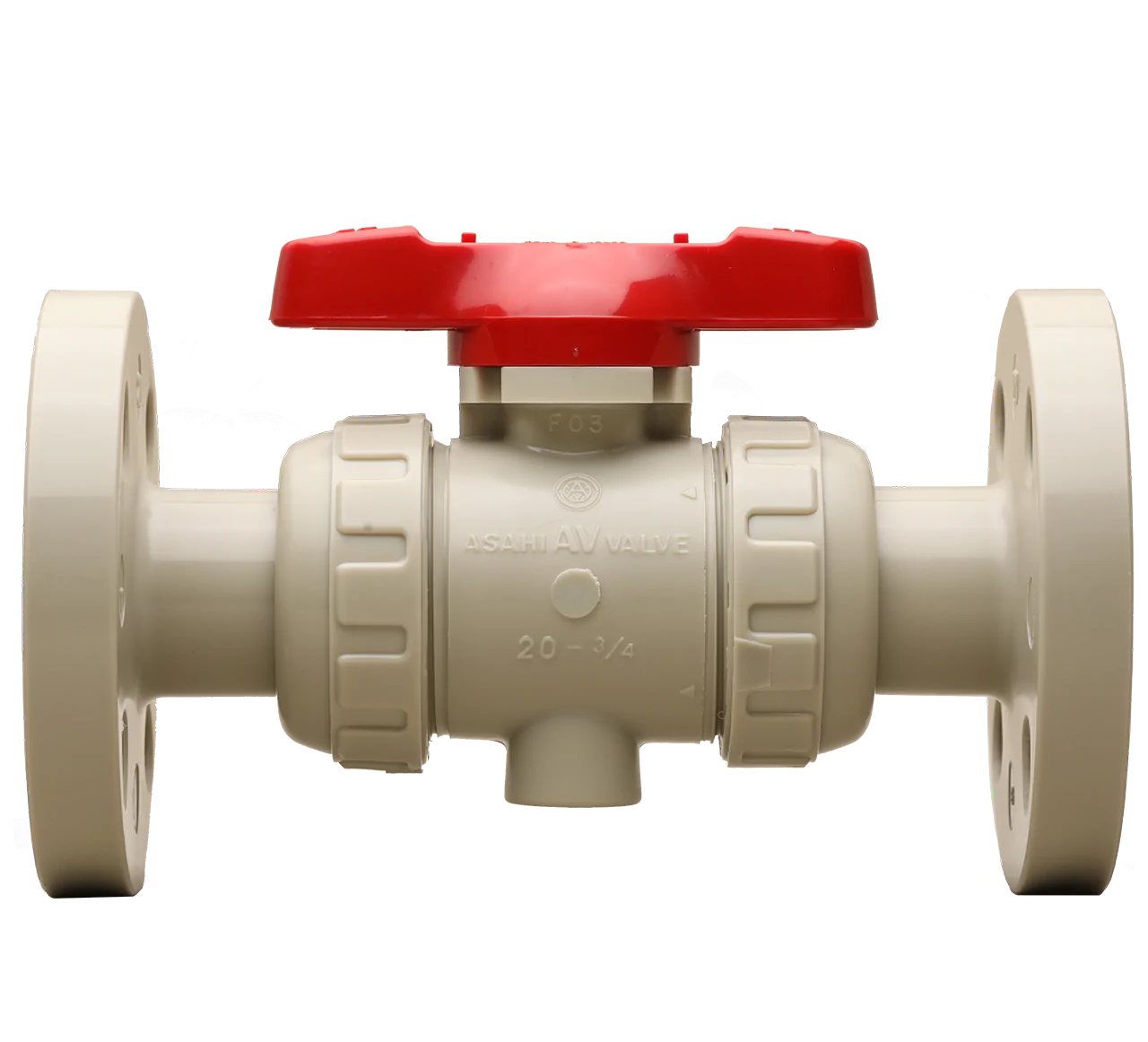

Ball valves are ideal for situations where a dependable and quick shut-off is required. These properties make them suitable for a wide range of industries where a tight seal is essential, such as chemical processing, water treatment, and oil and gas. The ball valve is set apart by its spherical ball with a hole through the middle. When the hole is aligned with the flow, the valve is open, allowing fluid to pass. With a simple 90-degree turn of the handle, the ball is rotated to block the flow, creating an effective seal. This design minimizes pressure drop and resistance, making ball valves ideal for high-pressure and high-flow scenarios.

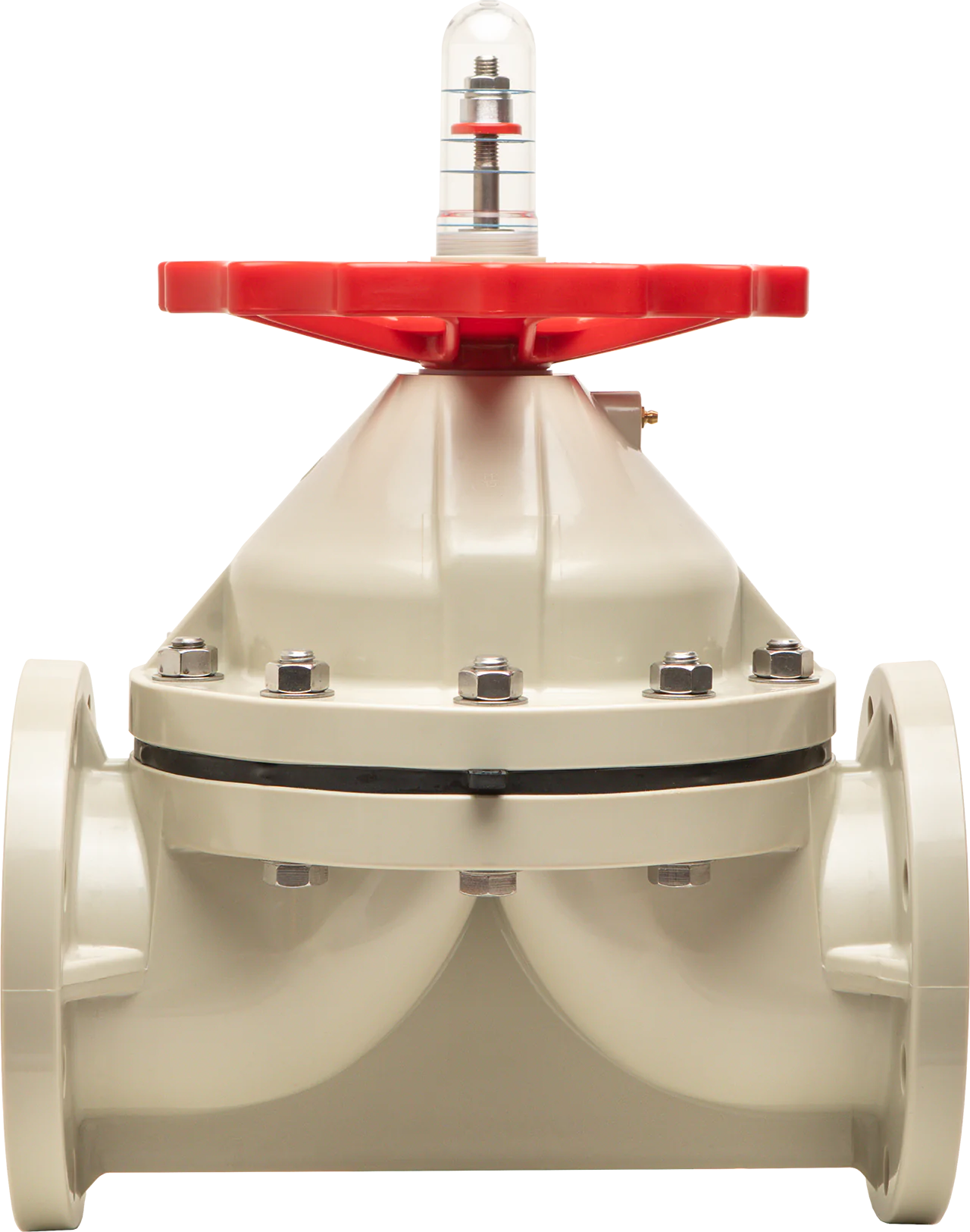

Diaphragm valves are designed to provide exceptional leak-proof performance, making them ideal for applications in hygienic and corrosive environments. These valves are widely used in industries such as pharmaceuticals, food and beverage, and chemical processing, where maintaining a sterile and contamination-free process is crucial. The diaphragm valve operates by using a flexible diaphragm that presses against a seat to control the flow of fluids. This design ensures a tight seal, preventing any leakage and minimizing the risk of contamination. Diaphragm valves are also easy to clean and maintain, which is essential in applications requiring frequent sterilization. Their simple and robust design allows for reliable operation and precise flow control, making them a versatile and dependable choice for a wide range of industrial processes.