Butterfly valves are essential for applications requiring efficient flow control and quick operation. These valves are widely used in industries such as water distribution, wastewater treatment, and HVAC systems due to their ability to handle large volumes of fluid with minimal pressure drop. The butterfly valve features a disc mounted on a rotating shaft. When the valve is fully open, the disc is turned parallel to the flow, allowing fluid to pass with minimal resistance. A simple quarter-turn of the handle rotates the disc to a perpendicular position, effectively blocking the flow. This design not only ensures rapid shutoff but also provides excellent throttling capabilities, making butterfly valves versatile for both on/off and modulating services. Their compact size and lightweight construction make them an economical choice for large diameter pipes, where space and weight considerations are critical.

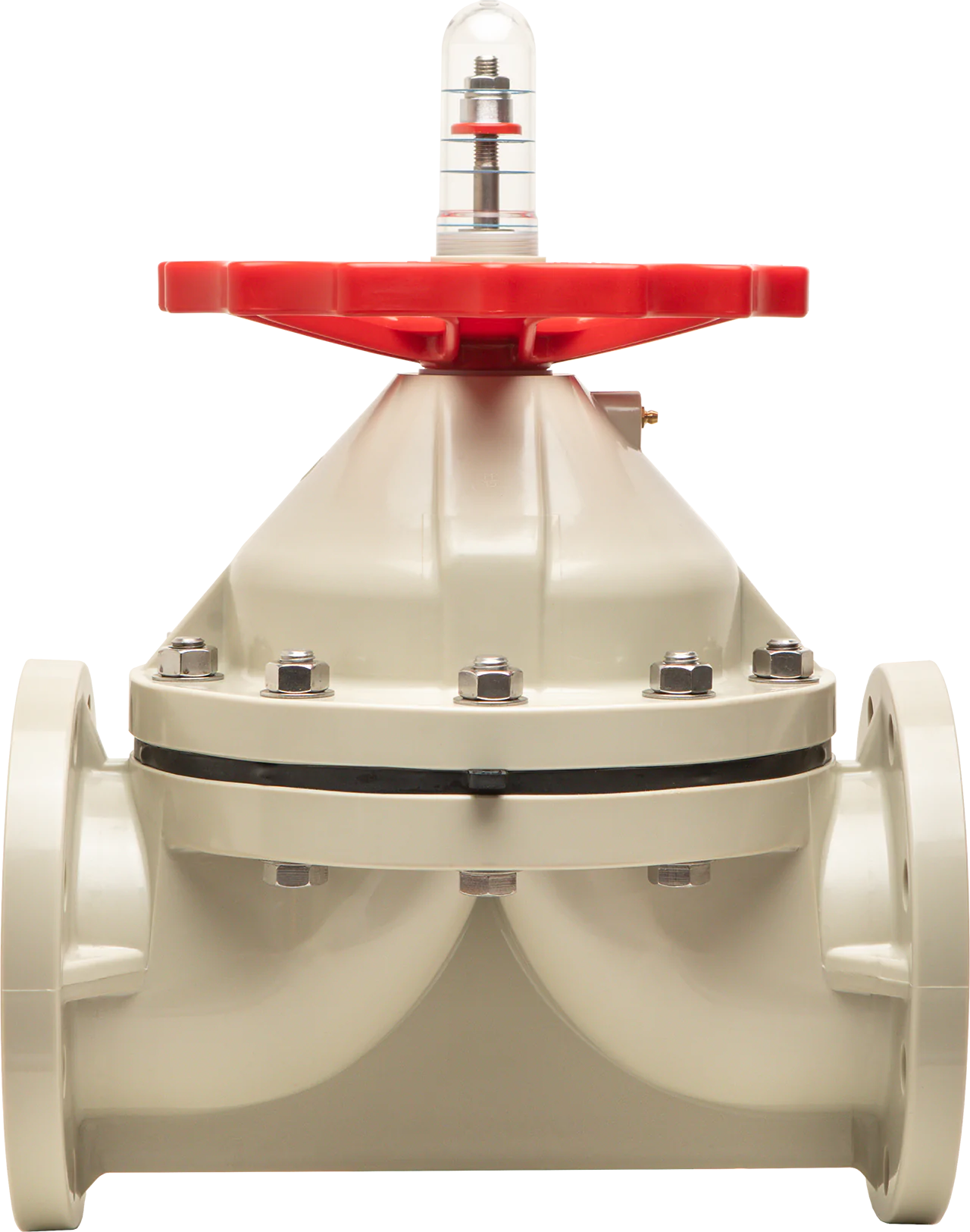

Diaphragm valves are designed to provide exceptional leak-proof performance, making them ideal for applications in hygienic and corrosive environments. These valves are widely used in industries such as pharmaceuticals, food and beverage, and chemical processing, where maintaining a sterile and contamination-free process is crucial. The diaphragm valve operates by using a flexible diaphragm that presses against a seat to control the flow of fluids. This design ensures a tight seal, preventing any leakage and minimizing the risk of contamination. Diaphragm valves are also easy to clean and maintain, which is essential in applications requiring frequent sterilization. Their simple and robust design allows for reliable operation and precise flow control, making them a versatile and dependable choice for a wide range of industrial processes.